|

Micro Vickers Hardness Tester Mitutoyo |

|

| HM-211 HM-211+TV unit HM-211 Auto Measuring

Unit |

|

| Model |

HM-211 |

HM-211 |

| Load(mN) |

98.07/196.1/294.2/490.3/980.7/1961/

2942/4903/9807 |

0.4903/0.9807/1.961/2.9424.903/9.807/19.61/29.42

49.03/98.07/196.1/294.2/490.3/1961/2942/4903/

9807/19610 |

| Load control |

Auto control(Load・Hold・Release) |

| Objective lens |

10X、50X |

10X、50X、100X |

| Max measuring range |

10X:700μm、50X: 140μm |

10X:700μm、50X: 140μm、100X |

| Workpiece table |

With digital micrometer/Table size 100x100mm/Move range 25x25mm/Min reading

1μm |

| Specimen size |

Height 133mm, 160mm backward to indentor center |

| Turret change |

Motor driven (Manual operation available) |

| Data display function |

LCD Color touch panel

Indent diagonal length:Max 5-digit, Min reading 0.01μm/Hardnes:Max 4-digit,

Min reading 0.1 hardness

Load・Hold・Release time, Judgement of(OK/NG, Hardness conversion, Indentor(HV/HK),

Table movement |

| Hardness conversion function |

SAE/ASTM/BS i860/DIN |

| Static arithmetic unit |

Number of data, Max value, Min value, Average, Upper limit, Lower limit,

Number of OK,

Number of +NG/ーNG, Standard deviation |

| Output |

Digitmatic :1CH、Centronics:1CH, RS232C : 1CH |

| Option |

TV camera・Auto measuring unit AUM・Auto positioning unit APU |

| Size・Weight |

400x640x600mm, 43kg |

|

HM-102 |

Model |

HM-101 |

HM-102 |

HM-103 |

| Load (mN) |

98.07/196.1/294.2/490.3/980.7/1961/

2942/4903/9807 |

| Objective lens |

10X(Observation)

50X (Measuring) |

10X, 50X (Observation、Measuring) |

| Indent diagonal length display |

0.2μm(Analog) |

0.1μm (Digitao) |

| Max measuring length |

140μm |

10X: 700μm/50X: 140μm |

| Specimen table |

Micrometer head:Analog, Movement range: 25x25mm、

Min reading: 10μm |

| Data processing unit |

ー |

Vickers, Knoop hardness calculating function,

OK/NG judgement function |

| Turret change |

Manual |

| CCD camera・TV monitor unit |

ー |

ー |

Standard |

| Output |

ー |

SPC, RS-232C, Centronics |

| Machine size・Weight |

Body:410x600x590mm, Control panel:165x260x105mm, 42kg |

|

|

Vickers Hardness Tester Mitutoyo |

|

|

| Model |

AVK-C0 |

HV-112 |

HV-113 |

HV-114 |

HV-115 |

| Load (N) |

9.807/49.03/98.07/

196.1/294.2/490.3 |

1.961/2.942/4.903/9.807

24.51/49.03/98.07/196.1 |

9.807/24.51/49.03/98.07/196.1 |

| Objective lens |

10X |

10X, 20X (Measuring availabe)

|

| Min display |

1μm |

0.1μm |

| Max measuring length |

700μm |

10X: 700μm, 20X: 350μm |

| Data processor |

ー |

Vickers・Knoop・Brinel hardness calculating function, Static arithmetic function,

Toughness bread calculation function |

| Turret change |

Manual |

Motor driven |

| Output |

ー |

RS-232C、Centronics、SPC, Output |

| CCD camera/TV monitor unit |

ー |

ー |

Standard |

ー |

Standard |

| Machine size・Weight |

200x600x705mm, 45kg |

Machine size:245x515x770mm, Control panel:165x260x105mm, 50kg |

|

|

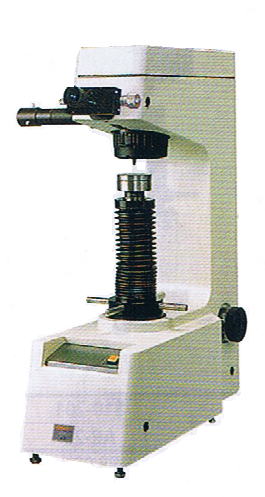

Rockwel Hardness Tester Mitutoyo |

|

| ARK-600 ATK-600 AR-20 AR-10 |

|

| Model |

ARK-600 |

ATK-600 |

AR-10 |

AR-20 |

| Initial load(N) |

98.07 |

29.42/98.07 |

98.07 |

98.07 |

| Load(N) |

588.4/980.7/1471 |

147.1/294.2/441.3

588.4/980.7/1471 |

588.4/980.7/1471 |

588.4/980.7/1471 |

| Load change |

Dial change |

Weigth change |

Dial change |

| Load control |

Initial load:Manual loading navigator function

Load: Auto(Load・Hold・Release) |

Initial load:Manual adjusting

Load:Auto(Load・Hold・Release) |

| Display |

Digital 4-digit display (LCD) |

Reading indicator on scale |

| Function |

OK/NG judgement, Loading navigator, Hardness offset function |

Auto set gauge, Zero setting not required |

| Output |

RS-232C/SPC output |

- |

| Size・Weight |

210X486X680mm, 40kg |

210x486x720mm, 42kg |

215x455x682mm, 38kg |

210x486x680mm, 40kg |

|

|

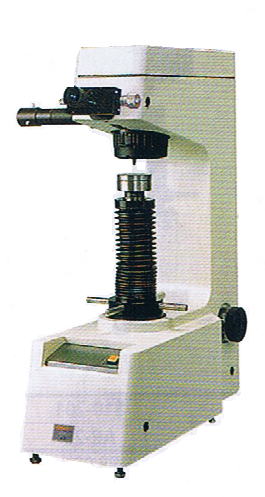

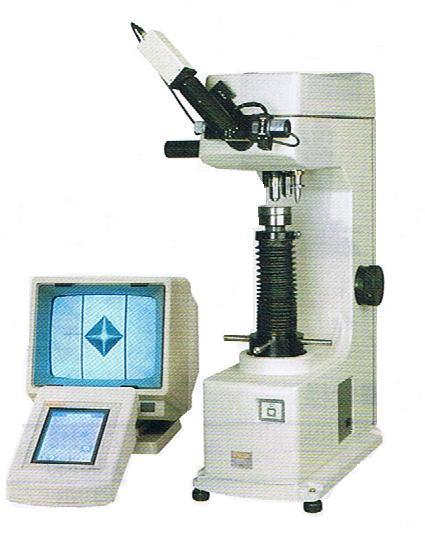

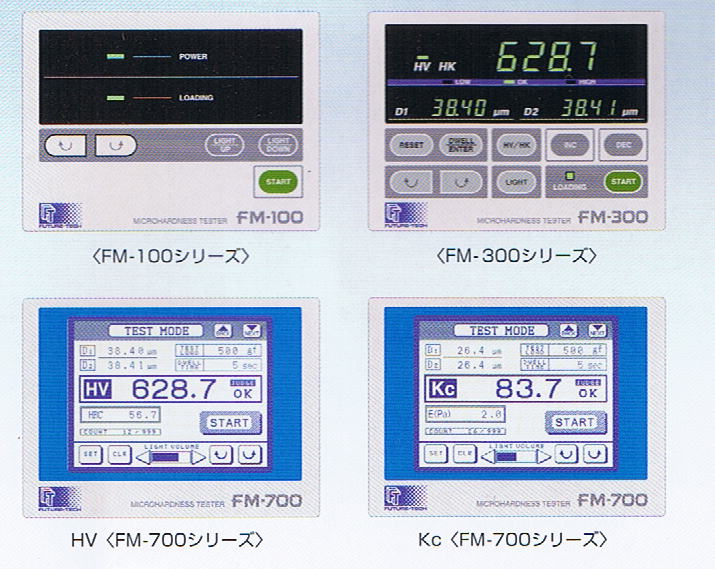

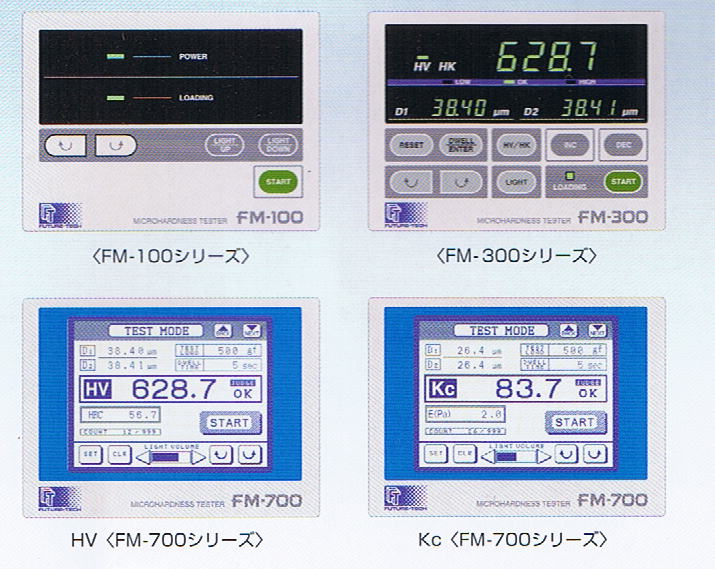

Micro Vickers Hardness Tester Future-Tech |

|

|

| Model |

FM-100e |

FM-100 |

FM-300e |

FM-300 |

FM-700e |

FM-700 |

| Test load |

A type |

mN: 98.07 245.2 490.3 980.7 1,961 2,942 4,903 9,807

gf : 10 25 50 100 200 300 500 1,000 |

| B type |

mN: 49.03 98.07 245.2 490.3 980.7 1,961 2,942 4,903

gf:: 5 10 25 50 100 200 300 500 |

| C type |

mN: 245.2 490.3 980.7 1,961 2,942 4,903 9,807 19,614

gf : 25 50 100 200 300 500 1,000 2,000 |

| D type |

mN: 9,807 49.03 98.07 490.3 9,807 2,904 4,903 9,807/19,614

gf : 1 5 10 25 50 300 500 1,000/2,000 |

| Turret device |

Manual |

Auto |

Manual |

Auto |

Manual |

Auto |

| Diamond indentor |

Standard |

Vickers (HV) indentor 1 pc |

| Objective lens |

Standard |

10x, 20x |

| Option |

50x, 10x, Turret 3 pcs |

50x、10x(2 pcs), Turret 4 pcs |

| Eyepieces |

10x |

| Measuring microscope type |

Mechanical type |

Electronics type |

| Specimen max size |

Height:95mm, Depth:115mm |

| Machine size・Weight |

W 186x D450x H504mm, 40kg |

| Power source |

AC100/115/220V 50/60Hz (Selection on panel) (AC240V Request when ordering) |

|

|

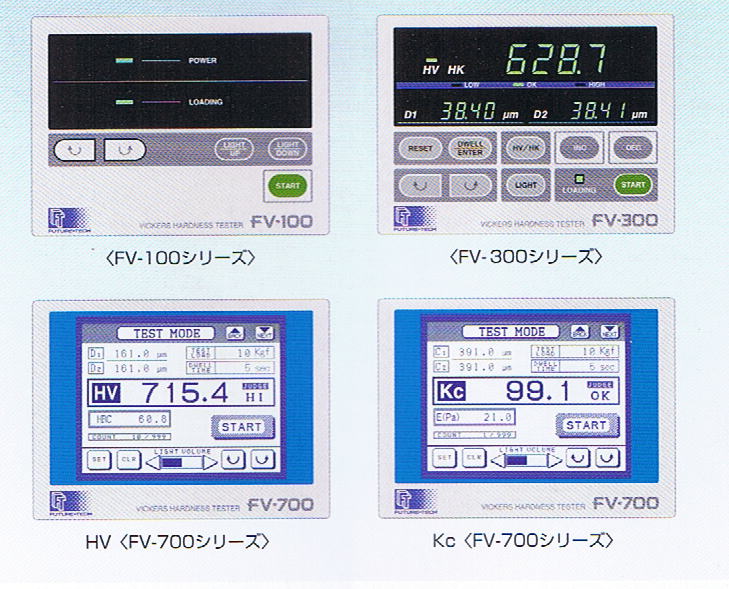

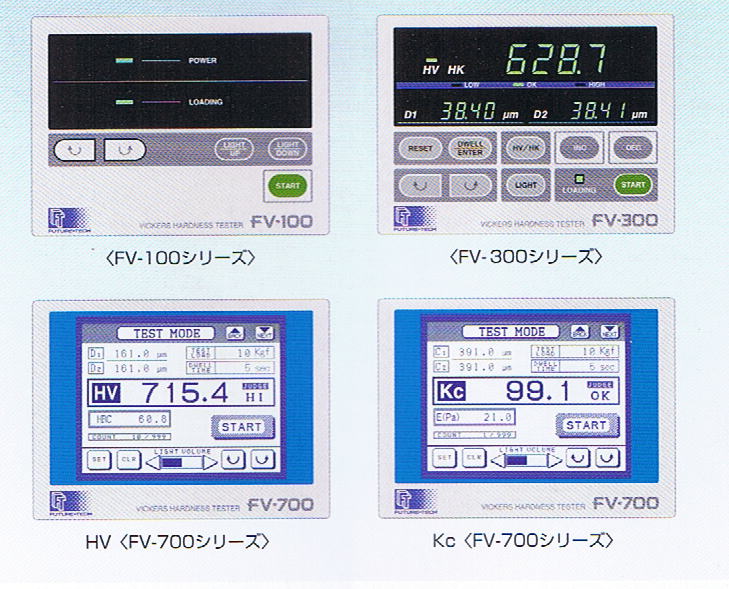

Vickers Hardness Tester Future-Tech |

|

|

| Model |

FV-100e |

FV-100 |

FV-300e |

FV-300 |

FV-700e |

FV-700 |

| Test load |

A type |

N: 9.807 19.61 29.42 49.03 98.07 196.1 294.2 490.2

kgf : 1 2 3 5 10 20 30 50 |

| B type |

N: 2.942 4.903 9.807 29.42 49.03 98.07 196.1 294.2

kgf : 0.3 0.5 1 3 5 10 20 30 |

| Turret device |

Manual |

Auto |

Manual |

Auto |

Manual |

Auto |

| Diamond indentor |

Standard |

Vickers(HV)Indentor 1 pc |

| Objective lens |

Standard |

A type 10x/B type 10x ,20x |

| Option |

Turret 3 pcs |

Turret 4 pcs |

| Eyepieces |

10x |

| Measuring microscope type |

Mechanical type |

Auto type |

| Specimen max size |

Height:210mm, Depth:165mm |

| Machine size・Weight |

W 196x D517x H690mm, 55kg |

| Power source |

AC100~240V 50/60Hz (Request when ordering) |

|

|

Rockwell Hardness Tester wiZhard Mitutoyo |

|

|

| Model |

HR-511 |

HR-521 |

HR-522 |

HR-533 |

| Initial load(N) |

29.42/98.07 |

| Test load(N) |

Super facial: 147.1/294.2/441,3 |

| Rockwell: 588.4/980.7/1471 |

| Brinell: 1839 |

Brinell: 61.29/98.07/153.2/245.2/306.4/

612.9/980.7/1226/1839 |

| Operation device |

Sheet switch operation |

Touch panel operation |

| Initial load change |

Changing by switch |

| Load control |

Initial load:Manual, Auto stop function・Test load:Auto(Load・Hold・Release) |

Initial Load:Motorized/Manual

Test :Auto(Load・Hold・Release) |

| Pipe shape specimen size |

Minimum pipe diameter:35mm(When special size indentor using:22mm) |

| Function |

Continuos measuring function on same specimen, Static arithmetic(Max. Min.

Average, Standard devision, Upper limit, Lower limit

Number of OK/NG, Range) HR-511: Through output(No display) |

| Offset compensation function |

Cylinderical compensation, Ball compensation, Offset compensation, Multi

point compensation, Graphic mapping function |

| Output |

RS-232C, Centronics output |

| Machine size・Weight |

Machine body: 250x670x605mm, 60kg Operation panel:165x260x105mm, 0.75kg |

*Brinell testing; Required Brinell indentoer and measuring microscope

device in option |

|

Rockwell Hardness Tester Future-Tech |

|

|

| Model |

FR-1e |

FR-1eL |

FR-2e |

FR-2eL |

FR-3e |

FR-3eL |

FR-1AN |

| Dial-gauge / Motorized |

Dial gauge/Motorized |

| Load |

Basic load |

N 98.07

kgf 10 |

N 29.42

kgf 3 |

N 29.42/98.07

kgf 3/10 |

N 98.07

kgf 10 |

| Test load |

N 588.4/98.07/1471

kgf 60/100/150 |

N 147.1/294.2/441.3

kgf 15/30/45 |

N 147.1/294.2/441.3

kgf 15/30/45

N 588.4/98.07/1471

kgf 60/100/150 |

N 588.4/98.07/1471

kgf 60/100/150 |

| Dial changing |

Weight changing by manual |

| Basic load positioning set |

Auto setting system(LED Level meter, Buzzer, Fine adjust not possible) |

Designated point on dial gauge |

| Load control system |

Auto (Load-Hold-Release) |

| Specimen max height |

190mm |

295mm |

190mm |

295mm |

155mm |

260mm |

170mm |

| Specimen max depth |

155mm |

150mm |

| Machine size |

FR-e: 190x443x675mm/FR-eL: 190x443x780mm |

195x460x677mm |

| Machine weight |

75kg |

80kg |

73kg |

78kg |

75kg |

80kg |

82kg |

| Power source |

AC100~240V 50/60Hz (Request when ordering) |

|

|

Rockwell Hardness Tester Wolpert-Wilson |

|

500MRD/500MRA-S |

600MRD/600MRD-S |

Model |

500RA |

500MRA

|

600MRD |

| 500MRA/S |

600MRD-S |

Hardness

standard |

A.B.C.F |

A,B,C,F |

A,B,C,D,E,F,G,H,K,L.,M,P,R,S,V |

| HRT,HRN |

N,T,X,Y |

| Resolution |

0.5 |

0.5 |

0.1 |

Hardness

display |

Hardness meter reading |

Auto、LCD display

Hardness value, Rockwell Load, Hold, Holding time, Upper/Lower limit value,

OK/NG indication, Specimen number, Average, Deviation, Repeat R |

| Load |

588. 980, 1471N |

Initial load:98N, 588, 980,1471N |

| Initial load:29.4N, 147.1, 294.2, 441.3N |

| Load control |

Manual,

Lever |

Auto (Initical load:Manual) |

| Load hold time |

Free |

Auto、4-99 second |

| Applied standard |

ISO6508, ASTM E-18, GB/T230.2 |

|

|

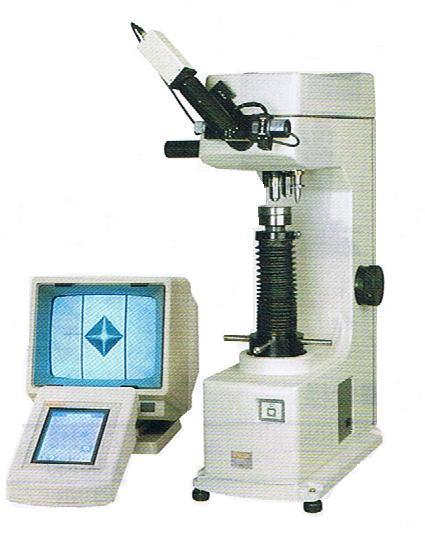

Micro Vickers Hardness Tester Wolpert-Wilson |

|

401MVA/402MVA |

430SVA/450SVA |

Model |

401MVA |

430/450SVA |

| 402MVA Auto-turret |

432/452SVA Auto-turret |

Hardness

standard(HV) |

0.01, 0.025, 0.05, 0.1, 0.2,

0.3, 0.5, 1.0 |

430SVA: 0.3. 0.5, 10, 20, 30 |

| 450SVA: 1, 2, 3, 5, 10, 20, 30, 50 |

| Test load |

0.098-0.245-0.49-0.98

-1.96-2.94-4.9-9.8N |

430SVA: 2.94-4.9-9.8-29.4-49-98-196-294N |

| 450SVA: 9.8-19.6-29.4-49-98-196-294-490N |

| Objective lens |

10x, 40x |

10x, 20x |

| Eyepiece lens |

10x |

| Max measureable area |

200μm(0.25μm) |

100x: 800μm(1μm)

200x: 400μm(0.5μm)

|

| Load control |

Auto (Load-Hold-Release) |

| Load hold time |

Auto, 5-99 seconds |

| Applied standard |

ISO6507, ASTM E384, GB/T4340 |

|

|

Brinell Hardness Tester Mitutoyo |

|

|

Model |

AVK-C0 |

| Load(N) |

4903/7355/9807/14710

19614/24517/29420 |

| Load change |

Weight changing by manual |

| Load control |

Manual control (Load-Hold-Release) |

| Load hold time |

Manual(Free) |

| Specimen max size |

Height:200mm, Depth:155mm |

| Machine size・Weight |

430x510x1100mm, 180kg |

|

|

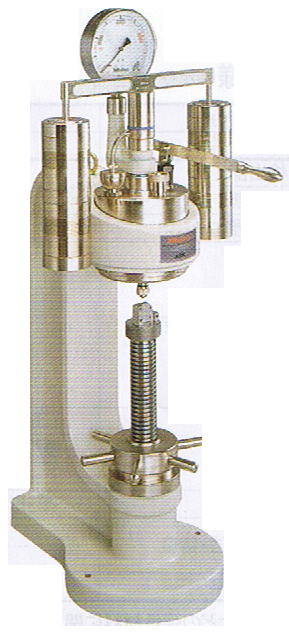

Hydraulic type Brinell Hardness Tester Imai

Seiki |

|

|

Model |

BO3 |

BO4 |

BO6 |

| Load(KN |

29.42/14.71/9.807/7.355/4.904 |

| Load change |

Weight changing by manual |

| Load control |

Manual control(Load-Hold-Release) |

| Load hold time |

Manual (Free) |

| Specimen max size |

Height:200mm

Depth:140mm |

Height:300mm

Depth:200mm |

Height:500mm

Depth:200mm |

| Machine size・Weight |

450x500x1120mm, 192kg |

450x600x1180mm, 230kg |

450x600x1480mm, 250kg |

|

|

Shore Hardness Tester Mitutoyo |

|

|

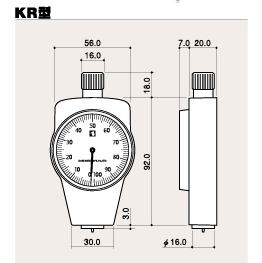

Model |

BO3 |

BO4 |

| Testing object shape |

General shape |

Exclusive roll shape |

| Standard |

JIS B7727 |

| Display |

Analog Graduation 0~140 Graduation unit 1HS |

| Accuracy |

35~95HS |

30~100HS |

| Tolerance in average value ±1.5 |

Tolerance in average value ±1.0 |

Tolerance in dispersion

Lower than75HS : 1.5

Upper than75HS: 2.0 |

Tolerance in dispersion: 1.5 |

| Specimen max size |

Height: 70mm Depth: 45mm(From indentor centre) |

| Machine size・Weight |

160x170x355mm 16kg |

|

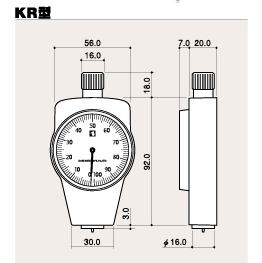

| Rubber ・Plastic Hardness Tester 〔Kori・Koubunshi-keiki・Teclock・Shimdzu〕 |

|

|

Rubber・Plastic Hardness Tester Kori-seiki |

|

|

| Model |

Purpose |

Applied standard |

Test load |

| A |

KR-14A :Standard |

General rubber |

JIS K 6253・ISO 7619

ASTM D2240 |

550-8,050mN

(56.1-821.1gf) |

| KR-24A :Needle setting |

| D |

KR-15D :Standard |

Hard rubber |

JIS K 6253・ISO 7619

ASTM D2240 |

0-44,450mN

(0-4,533gf) |

| KR-25D :Needle setting |

| KA |

KR-12KA :Standard |

General rubber |

JIS K 6301* |

539-8,379mN

(55-855gf) |

| KR-22KA :Needle setting |

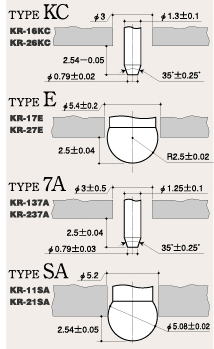

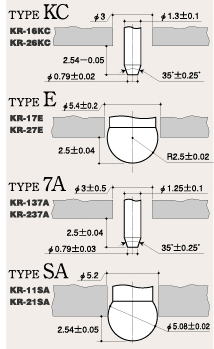

| KC |

KR-16KC :Standard |

Hard rubber |

JIS K 6301* |

980-44,100mN

(100-4,500gf) |

| KR-26KC :Needle setting |

| E |

KR-17E :Standard |

Soft rubber |

JIS K 6253 |

550-8,050mN

(56.1-821.1gf) |

| KR-27E :Needle setting |

| 7A |

KR-137A :Standard |

Plastic |

JIS K 7215・ ISO R 868A

ASTM D 2240A |

549-8,061mN

(56-822gf) |

| KR-237A :Needle setting |

| SA |

KR-11SA :Standard |

Soft rubber |

SRIS 010

JIS S 6050 |

539-8,385mN

(55-855gf) |

| KR-21SA :Needle setting |

|

|

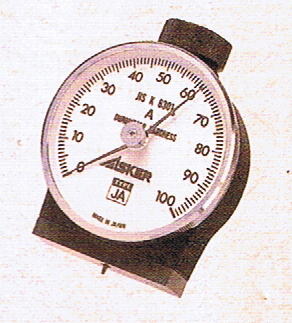

Rubber・Plastic Hardness Tester Koubunshi-Keiki |

|

|

Model |

A |

JA |

D |

E |

C |

| Test material |

General rubber |

Hard rubber

Plastic |

Sponge・Soft rubber |

| Standard |

JIS K6253 |

JIS K6301 |

JIS K6253 |

JIS K6253 |

JIS K7312 |

| Model |

JAL |

C1L |

F |

FP |

CS |

| Test material |

General rubber

(凹 shape) |

Sponge・Soft rubber

(凹 shape) |

Cushion material

Form rubber |

Cosmetic paff |

Styro form |

| Standard |

JIS K6301 |

JIS K7312 |

Asker F |

JIS K6253 |

Asker CS |

|

|

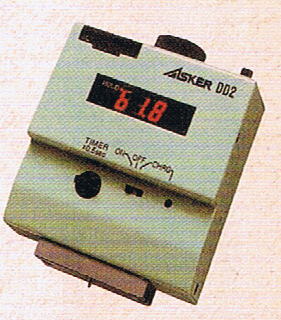

Digital type Hardness Tester Koubunshi-Keiki |

|

|

Model |

Applied standard |

Needle height |

Test material |

| DD2-A |

JIS K6253, K7215 |

2.50mm |

General rubber |

| DD2-D |

ASTM D2240 ISO868, 7619 |

Plastic |

| DD2-E |

JIS K6253 |

Soft rubber |

| DD2-C |

SRIS 0101 |

2.54mm |

String winding |

| DD2-JA |

JIS K6301 |

General rubber |

| DD2-JC |

Hard rubber |

| DD2-B |

ASTM D2240 |

2.50mm |

Semi hard rubber |

|

|

Rubber Hardness Tester Load Unit Koubunshi-Keiki |

|

|

Model |

P1-A |

P1-D |

P1-C |

PI-E |

| Applied standard |

JIS K6253/ISO7619/ASTM D2240 |

ASKER C |

JIS K6253 |

| Load system |

Coil spring type |

| Min reading value |

0.1 point |

| Needle size |

35°Conical-trapezoid

Edge diameter 0.79mm |

30°Conial-trapezoid

Edge R-size 0.1mm |

Diameter 5.08mm

Hemisphere |

Radius 2.50mm

Hemisphere |

| Output |

RS232C (PC/PRINT Change) |

| Power source |

AC100V 2A |

| Weight |

18kg |

22kg(Weight4kg) |

18kg |

■If not listed in the above, please contact us.   To top To top |

| Japan Technical Services Corporation ・ Zhuhai JTS Corporation TEL. +81-48-793-4858 FAX. +81-48-793-4859 |

Copyright 2011 JTS Corporation |