|

Precision Measurement・Tester・ISO Calibration |

| Japan Technical Services TEL. +81-48-793-4858 FAX. +81-48-793-4859 |

|

| CMM 〔Mitutoyo・Tokyo Seimitsu・TESA・Brown&Sharpe・Japan Technical〕 |

|

■ Crysta-Plus M433+QM-Data300 |

■ Crysta-Plus M433

| Model |

Crysta-Plus M443 |

Measuring

range |

X-axis |

400mm |

| Y-axis |

400mm |

| Z-axis |

300mm |

Accuracy

(20℃) |

Tolerance |

E=(3.0+4L/1000)μm |

| Probe tolerance |

4.0μm |

| Min reading |

0.0005mm(0.5μm) |

| Guide system |

Air bearing system |

| Clamping on axis |

One touch clamping system |

| Fine adjust movement |

All axis with fine movement |

Workpiece

size |

Max height |

480mm |

| Max weight |

180kg |

| Z axis balancing system |

Weight balancing |

| Air compressed |

Air pressure |

0.35MPa(Air source0.5~0.9MPa) |

| Air consumption |

50L/min(Air source 100L/min) |

| Machine weight |

410kg |

|

|

■ Crysta-Plus M574 MCOSMOS |

■ Crysta-Plus M500 Series

| Model |

Crysta-Plus M544 |

Crysta-Plus M574 |

Measuring

range |

X-axis |

500mm |

| Y-axis |

400mm |

700mm |

| Z-axis |

400mm |

Accuracy

(20℃) |

Tolerance |

E=(3.0+4L/1000)μm |

| Probe tolerance |

4.0μm |

| Min reading |

0.0005mm(0.5μm) |

| Guide system |

Air bearing |

| Clamping system |

One touch clamping system |

| Fine adjust movement |

All axis with fine movement |

Workpiece

size |

Max height |

595mm |

| Max weight |

180kg |

| Z-axis balancing system |

Weight balancing |

| Air compressed |

Air pressure |

0.35MPa(Air source 0.5~0.9MPa) |

| Air consumption |

50L/min(Air source 100L/min) |

| Machine weight |

512kg |

646kg |

|

|

■ Crysta-Plus M70106 |

■ Crysta-Plus M700 Series

| Model |

Crysta-Plus M776 |

Crysta-Plus M7106 |

Measuring

range |

X-axis |

700mm |

| Y-axis |

700mm |

1000mm |

| Z-axis |

600mm |

Accuracy

(20℃) |

Tolerance |

E=(4.5+4.5L/1000)μm |

| Probe tolerance |

5.0μm |

| Min reading |

0.0005mm(0.5μm) |

| Guide system |

Air bearing system |

| Clamping system |

One touch clamping system |

| Fine adjust movement |

All axis with fine adjust movement |

Workpiece

size |

Max height |

800mm |

| Max weight |

500kg |

800kg |

| Z-axis balancing system |

Weight balancing system |

| Air compressed |

Air pressure |

0.4MPa(Air pressure0.5~0.9MPa) |

| Air consumption |

50L/min(Air source 100L/min) |

| Machine weight |

1451kg |

1697kg |

|

|

|

TESA MICRO-HITE 3D CMM, Manual type TESA |

|

|

■ Measuring accuracy U1=3+3L/1000mm , U1=2.5+3L/1000mm

■ Triangle construction designing on X axis for stability

■ High accuracy design employed non-contact incremental scale

■ Simple operation by an independent control panel

■ Versatile measuring mode by measuring software「REFLEX」

■ Non contact measuring system equipped with CCD camera

■ Achieved critical measurement mechanism with fine adjustment movement |

| Model |

Basic, I, F, Fi |

HP(High-precision) |

| Measuring range(X・Y・Z) |

460x510x420mm |

Workpiece size

(X・Y・Z) |

600x750x430mm |

| Repeatability |

3μm |

2.5μm |

| Unknown tolerance U1 |

(3+3L/1000)μm |

(2.5+3L/1000)μm |

| Unknown tolerance U2 |

(3+4L/1000)μm |

(2.5+4L/1000)μm |

| Resolution |

0.001mm |

| Max travelling speed |

760mm/second |

| Temperature condition |

20±1℃ |

| Temperature in use |

13~35℃ |

| Machine size |

970x1620x930mm |

| Machine weight |

190kg |

| Required air pressure |

4.8~8.3bar |

| Air required |

21Litre/minute |

| Power required |

115~230VAC, 50/60Hz, 0.3~0.7A |

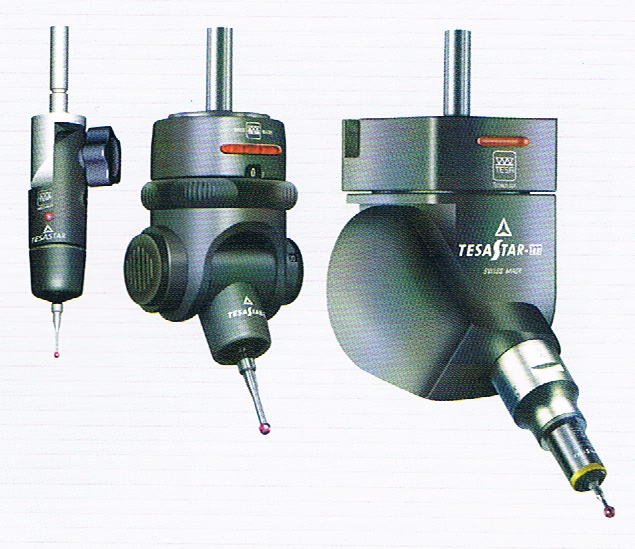

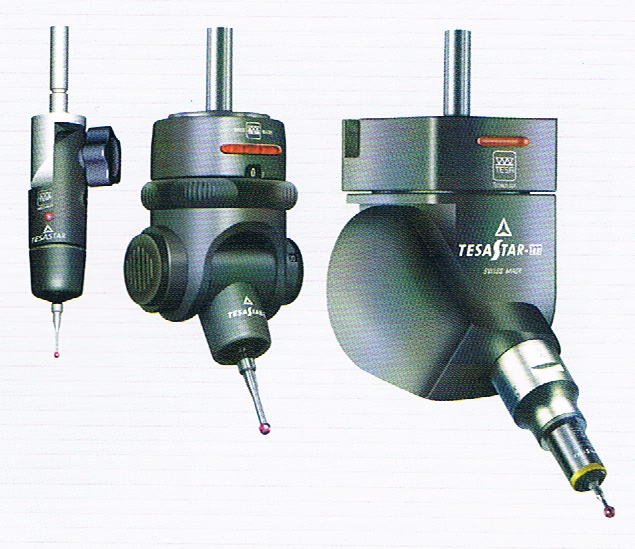

● TESA Star

Simple probe designed with constant measuring pressure

Realized high cost-performance

● TESA Star i

In-box type proble possible 169 positioning (15degree division)

Calibration on every position data are stored in the control panel

■ Technical information on probe

| Model |

Repeatability in

single direction |

Positioning

repeatability

|

Measuring

pressure |

Number of

positioning |

| TESA Star |

≦0.75μm |

- |

0.1~0.3N |

- |

| TESA Star i |

≦0.35μm |

≦1.5μm |

0.1~0.3N |

168 |

|

|

|

■ Product line-up

| Model |

Specific specification |

Model |

Specific specification |

| MICRO-HITE 3D HP |

High accuracy type, TESA Star i

with fine adjust movement |

MICRO-HITE 3D i |

TESA Star i

(No fine adjust movement) |

| MICRO-HITE 3D Basic |

TESA Star

(No fine adjust movement) |

MICRO-HITE 3D F |

TESA Stari,

with fine adjust movement

|

| MICRO-HITE 3D i |

TESA Star i

with fine adjust movement

|

MICRO-HITE 3D Fi |

TESA Star i

with fine adjust movement |

|

|

|

Brown & Sharpe CMM Brown & Sharpe |

|

■ Global Classic SR ■ Global Performance |

Model |

Measuring range (mm) |

MPEe (μm) |

| Explorer |

500 x 700 x 500 |

2.6+3.5L/1000 |

| 700 x 1000 x 500 |

2.8+3.5L/1000 |

| 700 x 1000 x 680 |

2.8+3.5L/1000 |

| Global Classic SR |

500 x 700 x 500 |

1.9+3.3L/1000 |

| 700 x 1000 x 660 |

| Global Performance |

500 x 700 x 500 |

1.5+3L/1000 |

| 700 x 1000 x 660 |

| Global Advantage |

500 x 700 x 500 |

1.4+3L/1000 |

| 700 x 1000 x 660 |

|

|

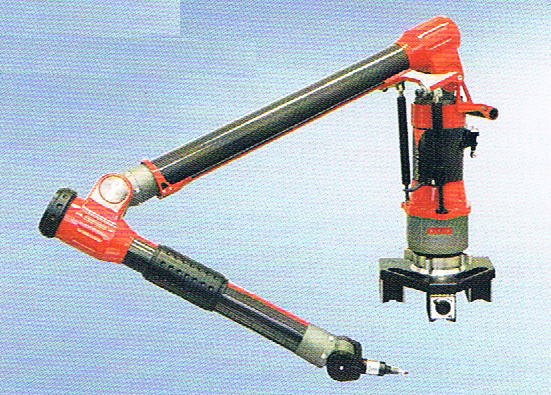

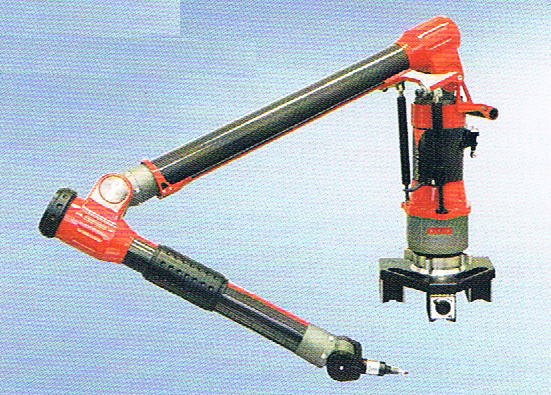

ROMER CMM (Universal type) ROMER |

|

■ OMEGA ■ Infinite 2.0 6-axis |

Model |

Measuring range |

Accuracy (mm) |

| OMEGA |

1.8m, 2.5m, 3.0m, 3.6m, 4.6m, 5.2m |

0.036 - 0.280 |

| SIGMA |

1.8m, 2.2m, 2.5m, 2.8m, 3.0m, 3.2m,

3.6m, 4.0m, 4.6m, 5.2m |

0.018 - 0.140 |

| FLEX |

1.8m, 2.2m, 2.5m, 2.8m, 3.0m,

3.6m, 5.2m |

0.022 - 0.168 |

| INFINITE 2.0 Plus |

2.4m, 3.6m |

0.017 - 0.043 |

| INFINITE 2.0 6-axis |

1.2m, 1.8m, 2.4m, 2.8m, 3.0m, 3.6m |

0.010 - 0.050 |

| INFINITE 2.0 7-axis |

1.8m, 2.4m, 2.8m, 3.0m, 3.6m |

0.024 - 0.070 |

| MultGage |

1.2m |

E=5+L/40≦18 (μm) |

|

|

Portable type CMM Spin-arm II Mitutoyo |

|

SA2-41-30 SA2-51-28 |

| Series |

Standard model 41 Series |

High accuracy model 51 Series |

| Model |

SA2-41-18 |

SA2-41-24 |

SA2-41-30 |

SA2-41-36 |

SA2-51-18 |

SA2-51-28 |

SA2-51-36 |

| Measuring range |

1850mm |

2400mm |

3000mm |

3600mm |

1800mm |

2800mm |

3600mm |

| Minimum reading |

0.001mm |

0.001mm |

| Accuracy |

Repeatability on

a fixed point |

±0.040mm |

±0.050mm |

±0.080mm |

±0.110m |

±0.020mm |

±0.032mm |

±0.055mm |

| Accuracy |

±0.080mm |

±0.090mm |

±0.112mm |

±0.135m |

±0.035mm |

±0.045mm |

±0.076mm |

| Accuracy for distance |

±0.055mm |

±0.070mm |

±0.110mm |

±0.155m |

±0.023mm |

±0.041mm |

±0.068mm |

| Joint construction |

2・2・2 |

2・2・2 |

| Machine weight |

4.6kg |

5.1kg |

5.3kg |

5.5kg |

7.5kg |

7.97kg |

8.65kg |

| Probe |

φ15mm, φ6mm, φ3mm, Point probe (1 each) |

φ15mm, φ6mm, φ3mm, Point probe (1 each) |

|

| Series |

Hgih accuracy model 51Plus Series |

7-joint model 51SC Series |

| Model |

SA2-51-24Plus |

SA2-51-36Plus |

SA2-51-18SC |

SA2-51-28SC |

SA2-51-36SC |

| Measuring range |

2400mm |

3600mm |

1800mm |

2800mm |

3600mm |

| Minimum reading |

0.001mm |

0.001mm |

| Accuracy |

Repeatability on

a fixed point |

±0.021mm |

±0.025m |

±0.040mm |

±0.055mm |

±0.080mm |

| Accuracy |

|

|

±0.050mm |

±0.060mm |

±0.080mm |

| Accuracy for distance |

±0.025mm |

±0.058mm |

±0.035mm |

±0.064mm |

±0.100mm |

| Joint construction |

2・2・2 |

2・2・2 |

| Machine weight |

7.82kg |

8.65kg |

8.05kg |

8.50kg |

9.13kg |

| Probe |

φ15mm, φ6mm, φ3mm, Point probe(1 each) |

φ15mm, φ6mm, φ3mm, Point probe(1 each) |

|

|

Rational CMM Japan Technical |

|

|

Full automated model |

| Model |

CMS-554C

CMS-574C

CMS-584C |

CMS-665C

CMS-685C

CMS-6105C |

CMS-886C

CMS-8106C

CMS-8126C |

CMS-10108C

CMS-10128C

CMS-10158C |

| X |

500 |

600 |

800 |

1000 |

| Y |

500/700/800 |

600/800/1000 |

800/1000/1200 |

1000/1200/1500 |

| Z |

400 |

500 |

600 |

800 |

| Measuring accuracy |

MPEe=(3.0+L/300)μm |

MPEe=(3.5+L/200)μm |

| Resolution・Max speed |

0.5μm 300mm/s |

| Manual model |

| Model |

CMS-564M |

CMS-584M |

CMS-685M |

CMS-6105M |

| X |

500 |

500 |

600 |

600 |

| Y |

600 |

800 |

800 |

1000 |

| Z |

400 |

400 |

500 |

500 |

| Measuring accuracy |

Space accuracy MPEe=(3.5+L/250)μm Single-axis accuracy MPEe1=(3.0+L/250)μm |

| Resolution |

0.5μm |

■High Precision Model ASM Series

●High Performance Measuring Model; Accuracy: ±0.07mm

|

Model |

Vertical Range |

Horizontal Range |

Effective Range |

Machine Height |

Machine weight |

| ASM-1000 |

1000 |

1000 |

1500 |

1850 |

210 |

| ASM-1500 |

1500 |

1200 |

1500 |

2300 |

240 |

| ASM-2000 |

2000 |

1200 |

1500 |

2950 |

300 |

| ASM-2500 |

2500 |

1200 |

1500 |

3400 |

340 |

■Standard model BK Series

●Standard Measuring Model; Accuracy : ±0.01+(L/50000)mm

|

Model |

Vertical Range |

Horizontal Range |

Effective Range |

Machine Height |

Machine weight |

| BK-1000 |

1000 |

1000 |

1500 |

1800 |

105 |

| BK-1500 |

1500 |

1200 |

1500 |

2300 |

155 |

| BK-2000 |

2000 |

1200 |

1500 |

2850 |

210 |

| BK-2500 |

2500 |

1200 |

1500 |

3300 |

240 |

| BK-3000 |

3000 |

1200 |

1500 |

3600 |

250 |

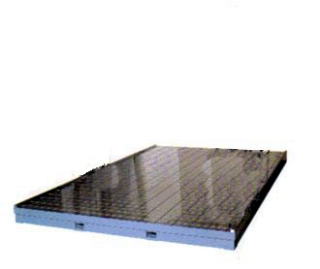

| ■ Digital control unit HI-DIGITER LT III for layout machineStan |

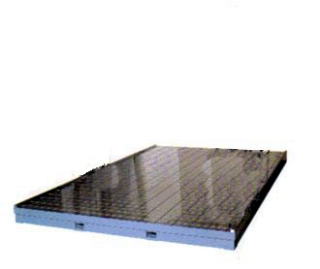

■ Precision Stage for layout machine |

|

Digital diplay : 6-digit, mm/inch(Change) |

|

Flatness: 0.03mm/1000mm |

| Minimum reading: 0.01mm |

Groove pitch: 250mm (±0.03mm) |

| Display axis : X/Y/Z |

Groove width: 10mm (+0.007~+0.030mm) |

| Data output : RS-232C |

2000x2000x250, 2000x3000x250,

3000x3000x250, 3000x4000x250,

3000x5000x250, 3000x6000x250mm |

| Power source : AC100V/120V |

■If your requiremetns not listed in the above, please contact us.   To top To top

|

| Japan Technical Services Corporation ・ Zhuhai JTS Corporation TEL. +81-48-7934858 FAX. +81-48-7934859 |

Copyright 2011 JTS Corporation |